Custom Mold Tooling & Tooling Transfers

Discover how ThermoFab’s expertise in precision and efficiency can elevate your mold tooling.

Precision and Efficiency

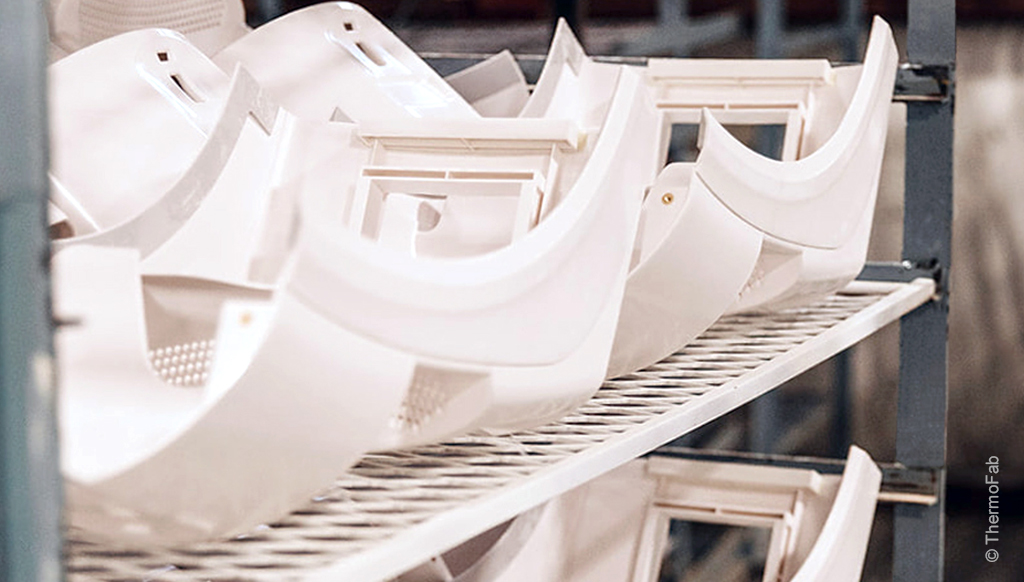

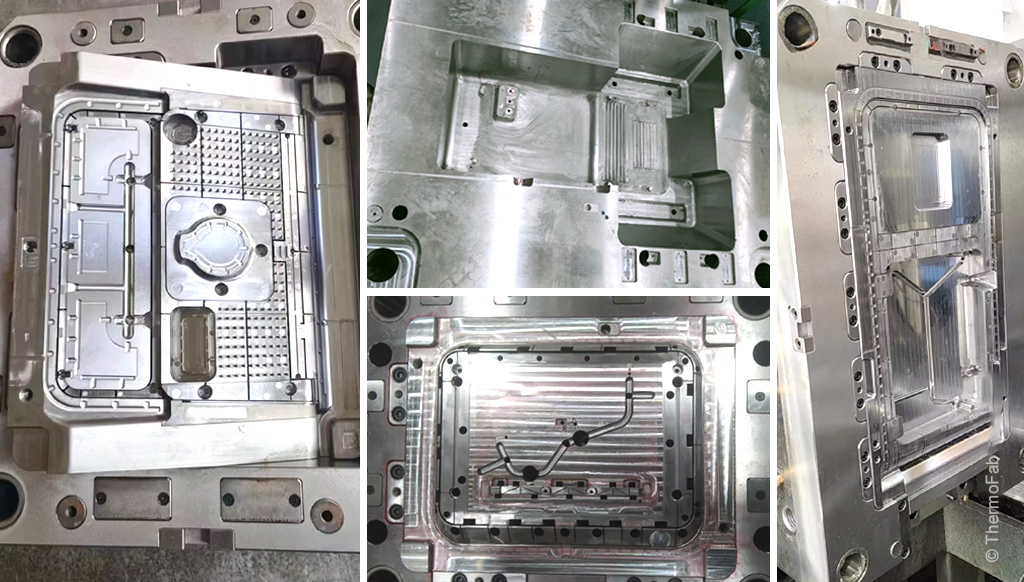

ThermoFab specializes in both pre-production and full production molds, utilizing premium materials like aluminum or P-20 steel, to ensure we deliver the highest quality molds. Our tooling is customized to meet your production requirements, enhancing the reliability and longevity of your molds.

Our commitment to quick turnaround times without sacrificing quality, evident in our lead time of 4-6 weeks. This efficiency enables us to provide superior molds efficiently, keeping your production on track.

Trust our experienced team to deliver mold tooling that excels in precision, durability, and efficiency. With ThermoFab, you can ensure your manufacturing process runs smoothly and effectively, supported by our dedication to high-quality mold tooling solutions.

Optimize Production with Nearshore Mold Tooling Transfers

Tooling transfers are crucial for businesses aiming to reclaim molds from overseas providers, reducing the need for costly new mold creation. Near-shoring these molds brings production closer to key markets, optimizing efficiency and control. ThermoFab’s new facility in Mexico will facilitate mold tooling transfers from Asia to Mexico, helping companies optimize costs, streamline logistics and reduce lead times, improve control over production, and enhance intellectual property protection due to the proximity and secure infrastructure.

We offer a structured transfer process, including thorough inspection and validation upon the molds’ arrival in Mexico, minimizing risks and ensuring that production quality remains consistent. Additional advantages of utilizing ThermoFab to perform near-shoring include:

- 0% import duties from China on tooling transfers into Mexico

- Cost-neutral transition from Asia, maintaining competitive cost targets

- Opportunities for tool rework and engineering enhancements to extend mold life

- Press sizes ranging from 200 to 900 tons for versatile production needs

- Inventory buffer options to maintain consistent supply

- Reduced transportation costs and import tariffs

- Full validation and inspection upon arrival in Mexico

- Better communication through closer time zones

- Greater responsiveness to quality and engineering needs

Expand the Longevity of Your Mold Tooling

Partnering with ThermoFab ensures your tooling investment is protected and sustained for long-term success. Our skilled team collaborates with you to provide mold modifications, regular maintenance, and repairs, keeping your molds in optimal condition. This preventative maintenance helps you achieve consistent results, minimize downtime, and maximize productivity.

Trust ThermoFab to extend the life of your tooling and enhance your production efficiency.