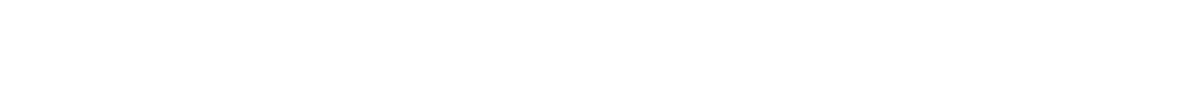

Machined Prototypes

ThermoFab excels in manufacturing precision machined prototypes using advanced CNC milling and turning processes, delivering high-quality parts with the tightest tolerances.

Comprehensive Machined Prototype Solutions

ThermoFab produces high-quality machined plastic prototypes using advanced CNC milling and turning processes. Our machining technologies ensure tight tolerances, intricate geometries and high-quality surface finishes. We work with a wide range of materials including ABS, PVC, Polycarbonate, acrylic, acetal (Delrin), Polypropylene, HDPE, UHMWPE, Nylon 6/6, PEEK, PTFE (Teflon), and G-10 Garolite. These materials provide chemical resistance and high-temperature tolerance.

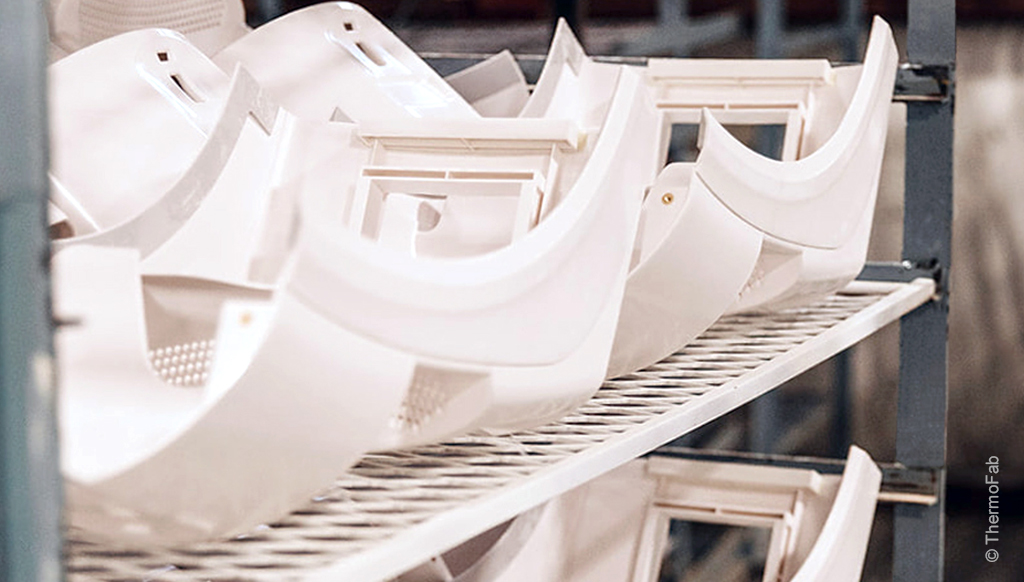

Additionally, we tailor our workflows to accommodate the entire lifecycle of your project. From initial prototyping to full-scale production and final assembly, our approach ensures seamless integration. This efficiency at every stage allows us to deliver high-quality, reliable solutions that meet your exact requirements.

Advantages of Machined Prototypes

Machined plastic prototypes play a crucial role across various industries, from medical devices to automation and robotics, offering numerous benefits.

- Precision & Accuracy: CNC machining achieves extremely tight tolerances and accuracy, enabling the creation of complex shapes and intricate details to meet your specific requirements.

- Cost-Effective: Machining plastic prototypes is a cost-effective solution, particularly for small production runs or intricate designs that would otherwise require expensive molds.

- Time-Efficient: CNC machining requires minimal prep time, leading to faster production times. Depending on the complexity of the part, prototypes can be machined within hours.

- Superior Finishes: Machined plastic surfaces are naturally smooth and can be further polished or treated to enhance the finish, ensuring high-quality final products.

- Secondary Operations: brass inserts, other hardware, assembly, painting etc

Size Capabilities

At ThermoFab we manufacture prototypes from 1 to 6 inches in diameter, with maximum flat stock lengths up to 36 inches and tolerances down to 0.001″, depending on your specifications. Our extensive expertise and cutting-edge technology ensure precision and quality in all our plastic machined prototypes.