Product Development

ThermoFab guides you through the product development process including, concept development and refinement, prototyping and process engineering to ensure your products are optimized for production.

Industrial Design

For customers needing assistance with enclosure design, our skilled industrial designers and mechanical engineers are here to help. We offer a comprehensive range of services, including concept development, design refinement, prototyping, and engineering finalization. Our goal is to create enclosures that meet your needs, uphold your brand aesthetics, and are mechanically optimized for efficient manufacturing.

Which process the right fit for your project? Explore key process options, cost considerations, and part attributes to make an informed decision. Our experts are here to guide you every step of the way—contact us today for personalized support.

Design for Manufacturing & Assembly (DFMA)

DFMA is a systematic approach focused on simplifying product design to improve manufacturability and assembly efficiency. This essential process in the product development cycle significantly improves the final product in terms of cost, profit, quality, performance, environmental compliance, and safety.

Our expert team collaborates closely with you to optimize your product design. By leveraging our extensive experience in production manufacturing, we guide you in making informed decisions for a successful product development process.

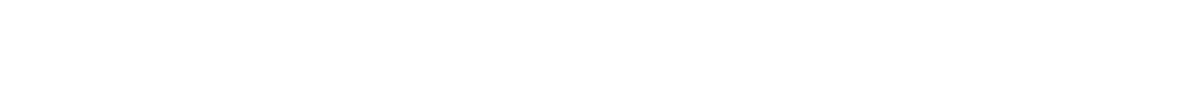

Bonded Assemblies

Having the ability to provide both thermoformed and injection molded parts allows ThermoFab the freedom to combine processes to gain efficiency. For instance, bonded assemblies, a common technique for thermoformed parts, can be applied to injection molded designs, resulting in lower tooling cost due to simpler tool designs without lifters or side action. Oversized parts can be made in multiple sections and bonded together to reduce the demand for huge injection mold machines. Or thermoformed parts can have injection molded ventilation features or complicated fastener blocks bonded on, reducing secondary operations costs. Bonded parts are typically indistinguishable from non-bonded parts.

Process Engineering

Process engineering plays a vital role in manufacturing, delivering significant benefits such as cost savings, improved efficiencies, and enhanced product quality. Our expert process engineers work closely with operations to develop a comprehensive action plan. This strategic plan anticipates potential process and equipment issues, addressing them proactively to prevent disruptions. Our optimized processes ensure that products consistently meet all required quality and safety standards.