Rapid Prototyping

Specializing in transforming your innovative product ideas into precision prototypes.

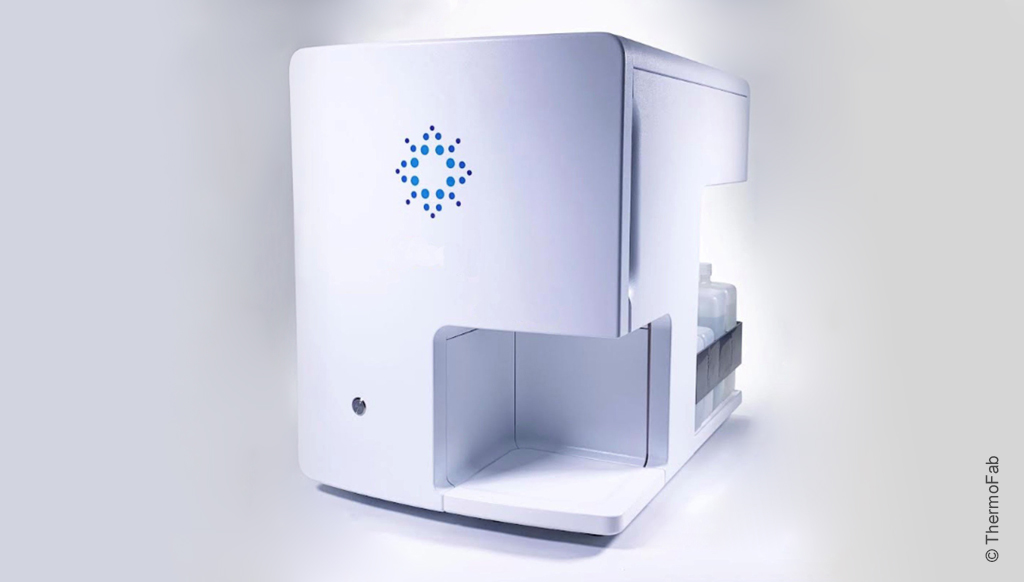

High-Quality Rapid Prototyping Solutions

At ThermoFab, our skilled team specializes in rapidly transforming your ideas into tangible, high-quality prototypes. We optimize our tooling for smaller production runs to ensure cost-effectiveness without compromising precision. Utilizing advanced 3D printing technology and precision machining we deliver prototypes that align perfectly with your specifications, with 3D printing capabilities for components as large as 4 ft.

Whether you’re looking for quick design iterations or to demonstrate a new concept, we are equipped with the tools and expertise to expedite the rapid prototyping process, helping you bring your innovations to market faster.

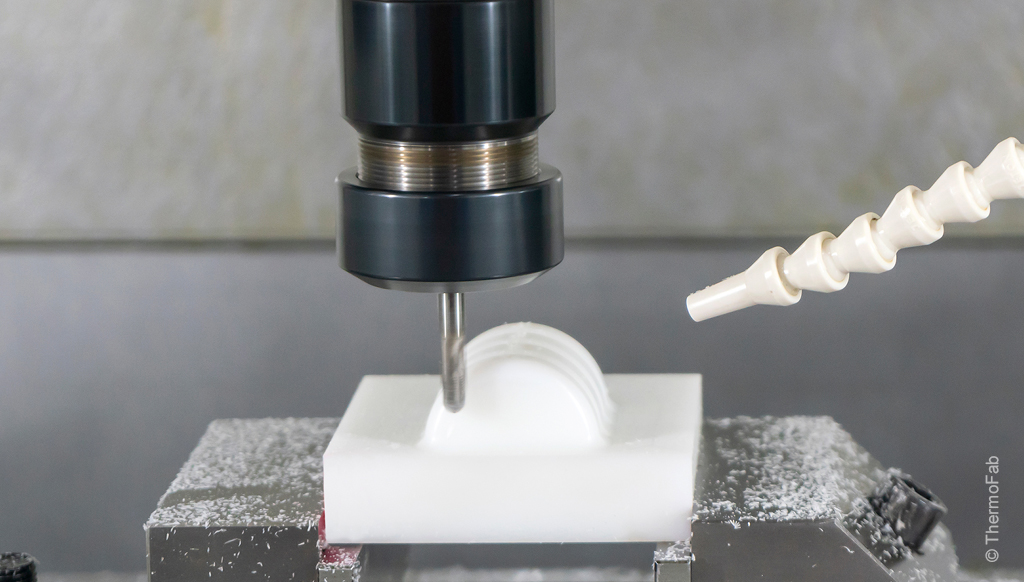

ADVANTAGES OF MACHINED PROTOTYPES

Machined plastic prototypes play a crucial role across various industries, from medical devices to automation and robotics, offering numerous benefits.

- Precision & Accuracy: CNC machining achieves extremely tight tolerances and accuracy, enabling the creation of complex shapes and intricate details to meet your specific requirements.

- Cost-Effective: Machining plastic prototypes is a cost-effective solution, particularly for small production runs or intricate designs that would otherwise require expensive molds.

- Time-Efficient: CNC machining requires minimal prep time, leading to faster production times. Depending on the complexity of the part, prototypes can be machined within hours.

- Superior Finishes: Machined plastic surfaces are naturally smooth and can be further polished or treated to enhance the finish, ensuring high-quality final products.

- Secondary Operations: brass inserts, other hardware, assembly, painting etc

Learn more about our precision machined prototype solutions

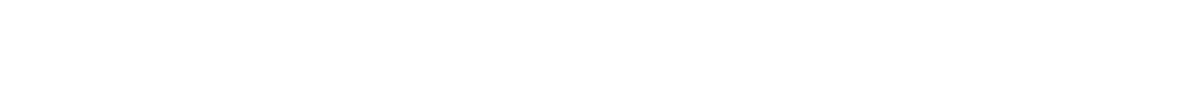

COLLABORATIVE APPROACH

At ThermoFab, we prioritize a tailored, client-focused strategy in every project. Leveraging our extensive training and experience in production manufacturing, our team will collaborate closely with you to select cost-effective materials and optimize your prototype designs for manufacturing and assembly.

Our commitment to DFMA (Design for Manufacturing and Assembly) principles, enables us to proficiently streamline production processes. Ensuring final prototypes are accurate to your specifications and also suited for large-scale production.

DESIGN VALIDATION

Prototyping is a critical step in the design validation process, enabling thorough testing and evaluation of product concepts before proceeding to full-scale production. This approach not only ensures that the product meets all required specifications and functional requirements but also highlights potential design flaws early on.

With the ability to identify and address these issues, you can significantly reduce production risks, avoid costly modifications later in the development cycle, ultimately leading to a more reliable and robust final product.

If you choose to move your product into production, our team will collaborate with you on Design for Manufacturing & Assembly (DFMA) to ensure your product is optimized for efficient manufacturing.

functional prototypes

Our functional prototypes do more than just mimic the appearance of your final product; they are manufactured to demonstrate functionality, fit, and form. Our approach provides a comprehensive evaluation platform, from usability testing to durability assessments, enabling you to validate not only the design but also market interest. This crucial step ensures that every aspect of the product performs as expected in real-world applications, reducing risks, and maximizing the potential for a successful market introduction with your target audience.